Everyone in this industry knows that medical equipment must be sterilized. This guarantees the absence of dangerous microbes on medical instruments, protecting patient health and avoiding infections. Sterilization is essential not only for specific patient care but also for healthcare centers.

Sterilization can be defined as eliminating bacterial properties that enable a substance to be safely reused, thereby reducing the spread of diseases.

This guide discusses sterilization, its types, non-sterilization consequences, and the instruments involved in the process.

This guide will outline why sterilization is essential, the numerous steps involved, the consequences of wrong sterilization, and what is used in the process of sterilization.

Whether you are a healthcare employee, a hospital manager, or a person who works in a sterilization department, it is crucial to appreciate the concept of sterilization to enhance healthcare facility operations.

Let’s start from the basics

[ez-toc]

What is Medical Equipment Sterilization?

Sterilization aims to eradicate all microorganisms from medical equipment through an elaborate procedure. What you should know is this:

In healthcare, contaminated equipment can potentially cause healthcare-associated risks that are hazardous to the patient and the healthcare givers.

This process is often applied to equipment used in sterile body areas, such as operating instruments and tools that cannot be disinfected using common reagents.

Several sterilization methods can be used to eliminate microorganisms that may be present in equipment without damaging it.

Sterilization means there is no possibility of bringing pathogens into the patients’ bodies during medical procedures.

Therefore, there can be no possibility of setting up infections that would otherwise complicate the recovery process.

Why Should We Sterilize Medical Equipment?

In healthcare facilities, the medical equipment needs to be sterilized so that it is further ensured to deliver a healthy environment. The reasons are as follows:

- Prevention of Healthcare-Associated Infections: Hospital-acquired infections threaten patients in facilities if equipment used in surgeries or normal operations is not adequately sterilized; infected blood can spread from one person to another.Sterilization frees any instruments of microorganisms that may have been on them, thereby minimizing the spread of infections from one patient to another or from the same equipment.

- Cross-Contamination Prevention: Some hospital tools are invasive, so contamination is easy if uncleaned equipment is used between different patients.Stress on giving the right sterilization reduces the chances of one patient transmitting the disease to another in a safe and sterile environment.Nurses and other health care professionals can reduce cross-infection and, therefore, protect both patients and workers from potentially fatal diseases by properly sterilizing all equipments.

- Ensuring Patient and Staff Safety: Surgical or invasive patients are at high risk of developing an infection. Sterilization is said to free instruments meant for use in the medical field from any hazardous organism.Members of the healthcare fraternity are also safeguarded against likely exposure to infectious agents and so likely transmission of disease at the workplace.Contaminated tools may cause faulty functioning or reduced efficacy of several diagnostic or surgical instruments. Improper sterilization can be risky to the lives of patients and endanger the lives of healthcare professionals if infected.

- Maintaining Equipment Integrity: Sterilization makes it easy to maintain the functionalities of the required medical equipment. Cleaning decreases equipment usage and degradation, allowing homeowners to avoid costly repairs or replacements.

- Meeting Regulatory Standards: Services providers in the health sector are legally bound to set, adhere to, and implement standard measures on sterilization. Such standards are also country-specific, but most involve measures provided by the U.S. Food and Drug Administration (FDA), the Centers for Disease Control and Prevention (CDC), and the World Health Organization (WHO). If these requirements are not met, the individual or business in question may face severe action, decertification, and maybe legal penalties.

How to Perform Medical Equipment Sterilization?

The equipment sterilization process is divided into various appropriate methods for specific tools. Here are the main ones:

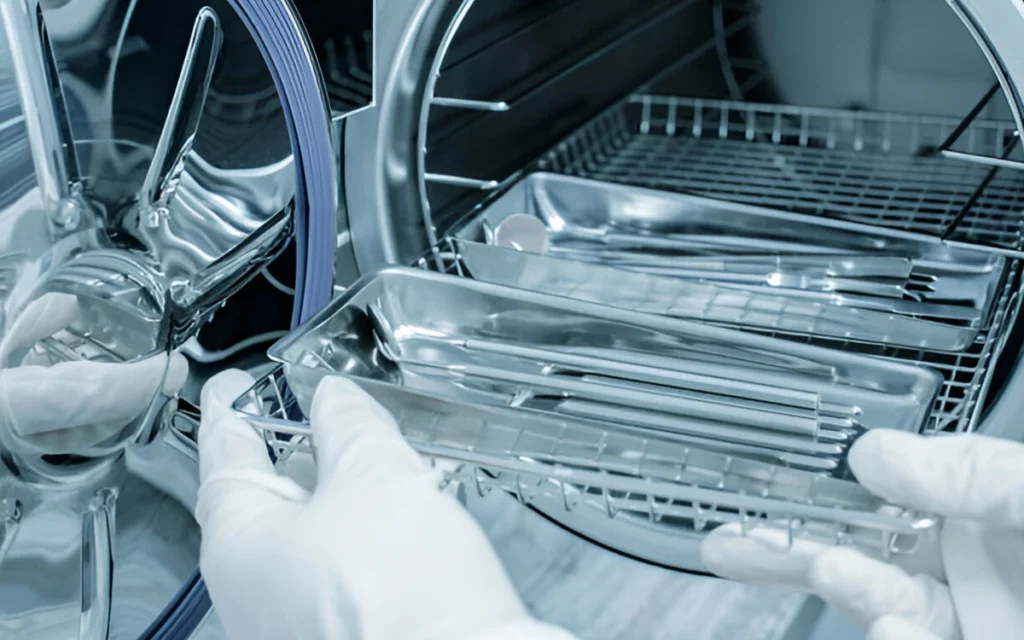

Autoclaving:

Autoclaving is the most popular and widely used instrument in healthcare because of its efficiency and dependability across the healthcare spectrum. This method employs the application of high-pressure steam with a range of 250- 274 F to sterilize equipment. Autoclaves are crucial in sterilizing all the principal cutting-edge surgical instruments, glassware, and textiles. The process ensures that all microbial life is destroyed by expounding the items to steam for a specific time.

Process:

- It is the simplest and most efficient technique for sterilizing most medical instruments. It uses high-pressure steam to eliminate microorganisms.

Advantages:

- Cost-effective.

- Fast and reliable.

- Steel is the most appropriate for most surgical instruments, especially the metallic ones.

Steps:

- It begins by putting the equipment into an autoclave that creates high-pressure steam.

- The equipment is then exposed to steam at approximately 121—134 ° C for a particular duration (15-30 minutes).

- At the end of the process, the temperature of the equipment is reduced before it is extracted.

Ethylene Oxide sterilization:

Ethylene oxide is a gas used to sterilize sensitive devices and instruments that cannot be exposed to heat, such as plastics and electronics. This sterilization takes its action by interfering with the reproduction cycle, preventing them from replicating.

Process:

- Ethylene oxide gas sterilizes articles that cannot be treated by steam. It is a colorless gas.

Advantages:

- Perfect for plastics or electronics that cannot withstand high temperatures.

- Prophylactic against many types of organisms and best against gram-positive cocci.

Steps:

- The equipment is put under a sealed container.

- A means for introducing ethylene oxide gas into the chamber is provided.

- The gas goes through the equipment, and over time (from one to six hours), it kills the microorganisms.

- Then, the chamber is aired to discharge the residual gas, and the apparatus is withdrawn.

Chemical Sterilization

Chemical sterilization treats articles or equipment with liquid chemicals or gases to eliminate microorganisms. This method is used when other sterilization methods are inappropriate because a particular type of equipment material is not well-suited.

Common Chemicals Used:

- Glutaraldehyde

- Hydrogen Peroxide

- Peracetic Acid

Process:

- This method involves using chemical solutions to destroy bacteria and other pathogens on the equipment. It’s suitable for sensitive equipment that cannot withstand heat or moisture.

Advantages:

- It is suitable for heat-sensitive materials like plastic.

- Suitable for small or single-purpose autoclaves only.

Steps:

- Chemicals such as disinfectants are either soaked into equipment or sprayed over equipment.

- The chemical solution stays on the equipment for 10-30 minutes often.

- The equipment is washed well and dried before being used again.

UV Sterilization

UV light can also be used for surface or small tool sterilization, mainly in operating or Clean rooms. UV sterilization is safe because it is free from chemicals and heat, making it another safe method for cleaning.

Process:

- UV light cleans the surface-specific zones by destroying the naked DNA of microbes, making them harmless.

Advantages:

- This one is useful for surface sterilization of equipment.

- The non-contact method is faster and cheaper than the other methods of determining the flow rate.

Steps:

- They also use a UV sterilization chamber while storing their equipment.

- The smart light is turned on, and the area of the equipment is disinfected.

- After the exposure period, The equipment is withdrawn from the game.

Dry Heat Sterilization

Dry heat is a slow technique that uses high temperature and duration. It does not apply to many materials, but it is used because it is more reliable than many other possibilities.

- Dry heat sterilization involves exposing the items to be sterilized to air at about 340 degrees F to kill microbial life. In situations where steam sterilization is not possible, heat sterilization can be used instead.

When Should Sterilization Be Done?

Sterilization should be done under specific conditions to ensure its effectiveness and safety:

Before Surgical Procedures:

- Whenever it is time for surgery, the instruments have to be cleaned to ensure no infection spread.

- Instruments must be cleaned and sterilized, regardless of whether they have been used on noninfected individuals.

After Exposure to Contaminants:

- Any bed, wheelchair, bed linen, dressing towel, mild, syringe, other accessories, any bed clothing accessories, or other articles of any nature which have been in contact with blood, any patient body fluid, or has been contaminated in any way should be disinfected immediately to avoid cross infections from one patient to the other.

Routine Sterilization:

- Sterilizing reusable equipment guarantees that such equipment is safe for reuse and that there is no accumulation of microorganisms.

After Handling Infectious Materials:

- Any equipment that is used in environments with infectious diseases or patients with compromised immune systems should be disinfected between each use to prevent cross-contamination.

In the course of Performing Daily Routine Procedures

- It is very important as sterilization wash is needed so that instruments used in health facilities will be safe for use. For example, thermometers, stethoscopes, and diagnostic equipment should be disinfected always, and where it was used on one patient, it should not be used on others.

Who has to take care of Sterilization?

Proper sterilization is a team effort, with several key players responsible for ensuring the process runs smoothly:

Sterilization Staff:

- Persons using sterilization equipment (autoclaves, chemical baths, UV sterilizers, etc.) must be professional staff.

- At this level, it is essential to ensure that sterilization procedures have been observed, review the cycles, and perform checks.

Healthcare Administrators:

- Check that the disposable and reusable medications are available or in short supply, autoclaves are operating, sterilizing solutions are in stock, and appropriate personnel are in the facility.

- Coordinate and implement sterilization policies and practices in healthcare organizations.

Healthcare Workers:

- Doctors, nurses, technicians, etc., ensure they clean the instruments before they go for sterilization.

- Instruments must be handled correctly to preserve the effectiveness of sterilization.

Risks of Improper Sterilization

Several problems associated with improper sterilization might have serious effects:

Healthcare-Associated Infections (HAIs):

- When sterilization is not well done, then equipment carrying infections will spread diseases to patients, making their stays longer in the hospital, causing associated complications and even life-threatening diseases.

Damage to Equipment:

- Lack of proper sterilization ruins delicate tools and puts them at risk of breaking down and needing to be replaced or repaired.

Reputational Damage:

- If any of the infections or equipment failure occurs and is associated with poor sterilization, the healthcare facility may face legal problems, loss of reputation, and patients’ trust.

Increased Healthcare Costs:

- Infections result in complications and the need to replace equipment, highly raising the hospitals’ costs, not only in the treatment but also in the legal aspect.

Types of Sterilization Processes

Medical equipment can be sterilized in several methods that are relevant to the kind of equipment. Steam, dry heat, chemical and plasma sterilization all have its advantages and disadvantages and thus they can all be used in different ways depending on the circumstance.

Steam Sterilization (Autoclaving):

- Autoclaves are efficient, dependable, rapid, and suitable for most metal and heat-retaining instruments in clinical practice.

Dry Heat Sterilization:

- Operates at high temperatures to clean material that should not be exposed to moisture, such as powders, oil, or glassware.

Chemical Sterilization:

- Chemical sterilization is appropriate for heating delicate instruments, as it involves using liquids to help remove pathogens.

Plasma Sterilization:

- One of the advanced techniques employs low-temperature plasma to sterilize sensitive products such as surgical instruments and endoscopes.

Where to Find Sterilization Equipment?

In the current world, the sterilization equipment supplier plays a crucial role in the sterilization process of medical instruments. Sterilization services at Winray med, the trusted medical equipment suppliers delivering the most modern equipment and are consistent with the industry benchmarks. The autoclaves, chemical sterilizers, and all the UV sterilizers they offer are meant for the healthcare industry.

Check Our Sterilization Solutions

For more details on affordable, high-quality sterilization equipment that guarantees patient safety and productivity of your equipment, do call Winraymed today.

Learning about the importance of sterilization and implementing the correct methods will mean that infection hazards are minimized and patient/employee safety is achieved.